-

Determination of resistance of any

fabric to abrasion is usually carried out by abrading the fabric under

specified conditions against a standard abradant. Although plane abrasion of

fabric surface does not cover all aspects of strains that are important in

determining service life, there are occasions when such a test gives useful

information.

Determination of resistance of any

fabric to abrasion is usually carried out by abrading the fabric under

specified conditions against a standard abradant. Although plane abrasion of

fabric surface does not cover all aspects of strains that are important in

determining service life, there are occasions when such a test gives useful

information.

-

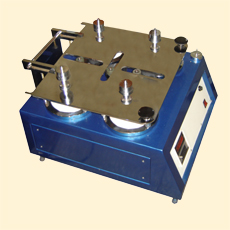

One of the standard equipment used

for this determination is the Martindale Abrasion Tester. This apparatus gives

a controlled amount of abrasion between fabric surfaces at comparatively low

pressures in continuously changing direction. Circular specimens of fabric are

abraded under known pressures under a motion which is the resultant of two

simple harmonic motions at right angle to each other. The resistance to

abrasion is estimated by visual appearance or by finding the loss in mass of

the specimens.

-

The PSI Martindale Abrasion

Tester consists of a plate which is give a motion combining two harmonic

motions at right angle through three rotating eccentric pegs, four number

specimen holders for mounting the fabric under test on, and four number abradent holders against which the test specimens are abraded.

-

The plate is supported on three

oil-lubricated felt discs and has three slots for locating the eccentric pegs

in. The pegs are rotated with the help of an electric motor, worm reduction

gearbox, and sprockets and chain arrangement such that the central peg is

rotating at a slower speed than the two outer pegs, which rotate at the same

speed. The movement of the pegs causes the plate to move in two mutually

perpendicular directions in simple harmonic motions, thus providing the

necessary abrading action.

-

The test specimens are mounted on

flat metallic discs and are backed with a thin layer of polyurethane foam. The

shafts of the specimen holders are guided vertically in bushes on the moving

plate. Thus the movement of the plate causes the specimen holders to move with

the plate, abrading it against the abradant fixed mounted in four holders

located below them. The force on the test specimens can be altered by adding

or removing dead weights from the specimen holders.

-

A five digit electronic pre-set

counter counts the number of rotation of outer pegs and stops the motor

automatically after a pre-set numbers of rotations. Templates for marking the

test specimens and abradant, disc weights to keep them flat during fixing, and

mounting jig for test specimens are provided as standard accessories.

-

The various components are mounted

on a sturdy fabricated steel base and are finished in grey hammertone stoving

painting and bright chrome or zinc plating to give them a corrosion resistant

finish.