Chin Strap Strength Tester, as per EN 397

The instrument comprises of a motorized load frame 500Newton capacity for applying tensile force up to 250 Newton. A specially designed artificial jaw assembly having two cylindrical rollers having 12.5mm diameter ± 0.5mm with their longitudinal axis separated by 76mm ± 2mm. An electronic controller with force transducer is incorporated to know the force being applied on the chin strap. After placing the helmet over wooden head form which is firmly fixed over a mounting fixture similar to one mentioned in ANSI a tensile force is applied up to 150 Newton at any variable speed & thereafter the rate of loading is controlled by specially designed electrical module which is integrated with DC motor & DC Amplifier which has a potentiometer with marking.

The potentiometer knob is set on specific graduation highlighted with marker to achieve rate of loading of at the rate of 20 N/min. ± 2N until the anchorage is released due to failure. The electronic controller is equipped with peak hold feature which will indicate the force at which the failure has occurred. The programmed controller wil have 2 set points & a timer user editable . The machine will stop automatically at firs set point for number of seconds entered for the timer & in that duration user has to set the potentiometer know to the highlighted graduation with which the rate of loading shall occur on the specimen.

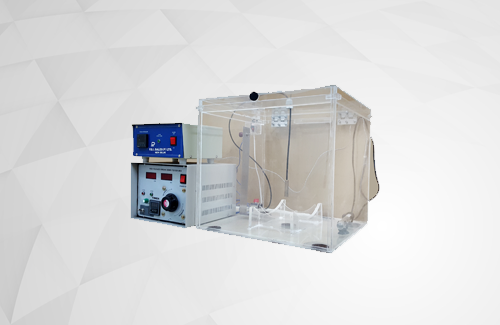

Electrical Resistance (High Voltage Breakdown) Tester,

as per IS : 2925

Tester consists of a plastic container with an acrylic frame placed in its center for keeping the helmet under test on the two electrodes held in suitable clamps, one located inside the helmet and the other in the bath. A high voltage source is provided with the equipment for supplying the test voltage upto 2000Volts. It consists of a variac range 3kV, a digital voltmeter & a digital mili-ammeter to indicate tripping current.

Electrical Resistance (A.C. High Voltage) Tester, as per ANSI, range 30kV :

- Input Voltage 240Volts A.C. 50Hz, 1 Ph.

- Output Voltage 0-30kV max. with facility for increasing the voltage at the rate of 1000Volts/second through a servo motor operated auto-variable transformer when unit is in HV ON mode.

- Current Meter in the range 0 - 30mA.

- Pre-set timer range 0 - 5min

- A vessel to contain fresh tap water, of sufficient size to immerse the inverted helmet to the water line.

- A frame for suspending the test sample in the water.

The H.V. Tester is air cooled & table mounted type compete with ON/OFF switch, HV & Mains Indicator Lamps, HV ON/OFF Push Button & Control.