PSI Sales is a well-known manufacturer of Horizontal Chain Rope Testing Machines based in Delhi. They specialize in creating high-quality machines that test the strength and durability of horizontal chains and ropes. This type of machine is essential for various industries, including construction and manufacturing. PSI Sales stands out in the market due to its focus on quality and customer satisfaction. They design their machines to meet international standards, ensuring that clients receive the best products available.

One of the reasons PSI Sales is leading the market is their commitment to affordable pricing. They understand that businesses want reliable equipment without spending too much money. That’s why they offer Horizontal Chain Rope Testing Machines at competitive prices in Delhi. Customers can be confident that they are getting great value for their investment. By balancing quality and cost, PSI Sales makes it easier for companies to access the machines they need for their operations.

PSI Sales also prides itself on its excellent customer service. They believe that after-sales support is crucial for building long-term relationships with clients. Their team is ready to help customers with any questions or issues they may encounter with their machines. This support goes a long way in ensuring that businesses can operate smoothly without any delays. Customers feel valued and appreciated, knowing help is just a phone call away when they choose PSI Sales.

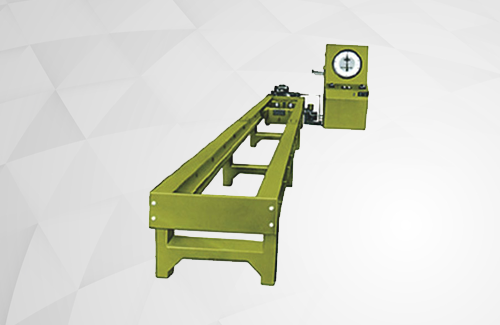

The machine offered by PSI Sales is designed with user-friendliness in mind. Operators can easily learn how to use it without needing extensive training. This is important for workplaces where efficiency is key. By making their machines simple to operate, PSI Sales helps businesses save time and minimize errors. This way, companies can focus on getting their work done quickly and effectively, knowing they have reliable testing equipment on their side.

In conclusion, PSI Sales is a trusted name in the manufacturing of Horizontal Chain Rope Testing Machines in Delhi. Their commitment to quality, competitive pricing, and strong customer support makes them a top choice for many businesses. With their user-friendly machines, customers can perform tests confidently, knowing they have a reliable partner in PSI Sales. Companies looking for efficient and affordable testing solutions will find everything they need with PSI Sales. Their strong market presence and dedication to satisfaction set them apart in the industry.

Features :

The design of the Electronic Horizontal Chain and Rope Testing Machine allows for testing that is not only highly accurate but also economical, fast, and versatile.

- Improved loading accuracy of ±1% in compliance with BS: 1610-1964 Grade A and IS: 1828-1975 Grade 1.0.

- Variable straining speeds to accommodate a wide range of materials.

- Motor-driven gear shafts allow quick and effortless adjustment of test length for fast specimen mounting.

- High reading accuracy ensured by a large, easy-to-read dial.

- Wide range of standard and optional accessories, including a load stabilizer.

- Large effective bed clearance enables testing of specimens of various sizes.

- User-friendly controls for simple and efficient operation.

- Robust and highly rigid straining frame for enhanced durability.

- Safety devices incorporated to ensure secure operation.

- Fully enclosed and protected pendulum mechanism.

- Precision load cell with a microprocessor-based system for accurate measurement.

- Optional Windows-based software for PC operation.

Application :

The machine for testing horizontal chains and ropes electronically is intended to assess the tensile strength of these materials.

Principle of Operation :

The machine operates through the hydraulic transfer of load from the test specimen to a load indicator housed separately. This hydraulic system is preferable as it eliminates the need for load transmission via levers and knife edges, which are susceptible to wear and can be damaged by shocks when test pieces break.

A hydrostatically lubricated piston exerts the load. The load cell detects the load, which transmits the pressure from the main cylinder to the specimen. The movement of the piston is conveyed to a rotary encoder via a rack and pinion system. Signals from both the load cell and the rotary encoder are processed in a microprocessor-based measurement panel, where load and displacement are displayed digitally. To manage the return movement of the pendulum, energy is effectively absorbed, providing dampening in case a specimen breaks suddenly.

Control Panel :

The power pack includes a drive motor, an oil tank, a control valve, and an electronic measuring panel, all of which make up the control panel.

Power Pack :

The unit produces a peak pressure of 200 kgf / cm2. The hydraulic pump delivers a steady flow of oil without pulsations, ensuring a very even application of load.

Hydraulic Controls :

Wheels that are operated by hand control the movement of fluid to and from the hydraulic cylinder. The oil flow can be adjusted infinitely. A regulating valve is part of the hydraulic system, ensuring that the rate of movement of the crosshead remains nearly constant.

Measuring Systems :

The measuring system in these machines includes a precise load cell to gauge load, a rotary encoder combined with a rack and pinion setup to assess displacement, and a microprocessor panel that displays both load and displacement in a digital format. This panel features a membrane keyboard that allows for quick taring of the load and resetting of displacement with a simple key press. Information on test outcomes, such as peak load, displacement at peak load, rupture displacement, U. T. S., and percentage elongation, is accessible on the panel.

The RS-232C serial interface allows for the transfer of test data to a computer. An optional Windows-based software is available for real-time plotting and data storage on a PC..

Accuracy and Calibration :

Electronic Horizontal Chain and Rope Testing Machines undergo strict monitoring for sensitivity, precision, and calibration throughout all manufacturing phases. Each machine is subsequently calibrated across its entire range following British Standards 1610-1964 and IS:1828-1975..

The Horizontal Chain Rope Testing Machine from MCS Electronic meets the standards of Grade "A" as per BS 1610-1964 and Grade 1.0 in accordance with IS 1828-1975. It ensures an accuracy of +1% across a range from 2% to 100% of the full load.