International Rubber Hardness Degree Meter

IRHD ( as per IS 3400 ( Part II ) 1980 ) meter is used to determine the hardness components where highlyaccuracy and reliable determination of the hardness is of extreme important. The principal behind determination of hardness by dead load apparatus is based on the measurement of the difference between the depth of indentation of a standard ball into the rubber under a small conduct force and a large indenting force

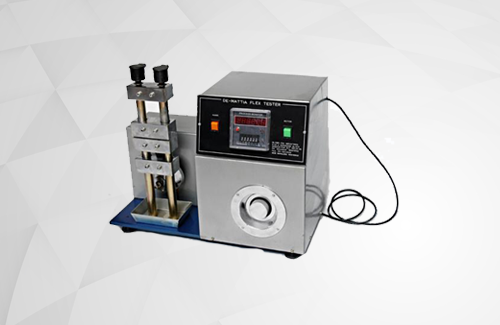

De Mattia Flex Tester

De Mattia Flex Tester ( as per IS 3400 ( Part 7, 8 ) 1977 IS 7016 ) , electrically operated provides information about the resistance of vulcanized rubber compounds, coated and treated fabrics to cracking when subject to flexing. Crack development in that part of the surface where stresses are set up during flexing, or if that part of the surface initially containing a crack, causes this crack to extend in the direction perpendicular to stress. This test also assesses the durability of material. The machine tests six specimens at a time.

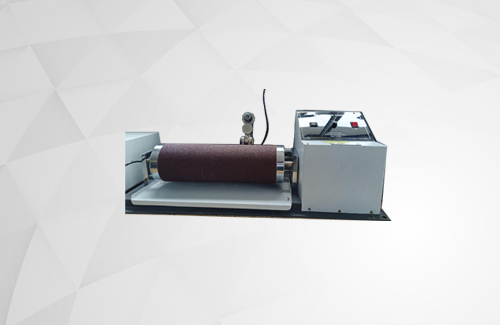

Din Abrasion Tester

Cylindrical test specimen of prescribed dimensions is drawn across a test emery paper with corundum of 60 grades at a constant force of application of 10 N and at a constant speed of 0.32 m/s, the abrasion distance being 40 m or in special cases 20m. An abrasive powering the range from 170mg to 220mg is allowable. The loss of mass of the test specimen in mg is determined to within 1mg by weighing and its volume loss calculated on the basis of the density determined according to DIN 53 479. The test procedure according to standard DIN 53516, provides a measuring method for assessing the resistance of elastomers to wear by rubbing. The determination of the volume loss by rubbing with a test emery of defined abrasive power by this method is suitable for comparative testing, for checking the uniformity of specified products and for specifications; however, the results of this test gives only limited information on the wearing behavior of elastomers in practice